Conveyor pulley

Chapter One: What is Conveyor pulley?

Conveyor pulley is a device installed in the conveyor system and serves as a crucial component to support and guide the conveyor belt. By providing power, it facilitates the smooth transportation of materials or goods. They typically consist of a cylindrical shaft and an outer casing. Conveyor pulleys can be classified into head pulleys and tail pulleys, used to drive the belt forward and backward, respectively. The head pulley is often connected to an electrically powered mechanism for providing power, while the tail pulley is used to adjust the belt tension.

To ensure the stable and efficient operation of the conveyor belt, the design and size of the Conveyor pulley are customized according to specific conveyor system requirements. You can contact us with your specific requirements, and our technical team will tailor a design exclusively for you. Feel free to reach out to us with any questions or inquiries.

Chapter two: Types of Conveyor pulley

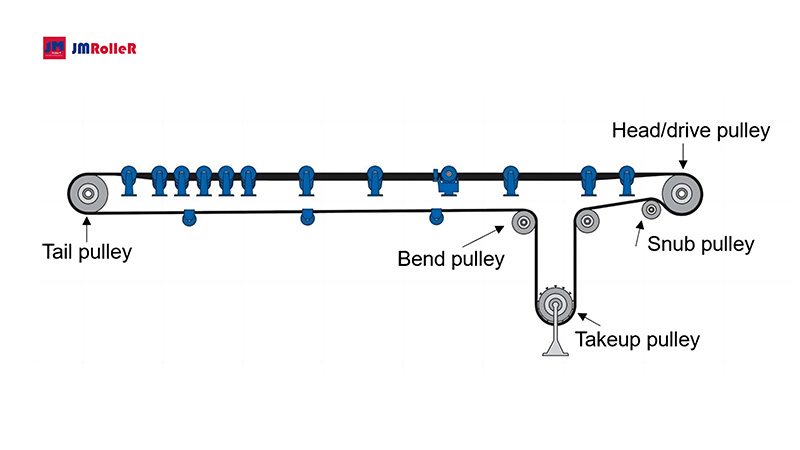

1. Drive Pulley: Used to drive the conveyor belt and typically installed at the head of the conveyor.

2. Tension Pulley: Adjusts the tension of the conveyor belt to maintain proper tightness and usually installed at the tail of the conveyor.

3. Bend Pulley: Changes the direction of the conveyor belt and typically installed at curved sections.

4. Snub Pulley: Increases the tension of the conveyor belt to ensure stable operation, usually installed in the middle of the conveyor.

5. Take-up Pulley: Adjusts the length of the conveyor belt to ensure proper tension and typically installed at the tail or support frame.

6. Magnetic Pulley: Used in specific scenarios to remove ferromagnetic materials, such as metal fragments, from the conveyor belt.

Each type of pulley plays a different role in the conveyor system, ensuring stable operation and efficient material handling. Conveyor pulleys are the backbone of material handling systems, enhancing efficiency, reliability, and safety across various industries. From providing power for material transportation to maintaining appropriate belt tension, facilitating direction changes, enhancing belt support, and cleaning contaminants, each type of pulley plays a critical role in optimizing conveyor performance.

As industries continue to rely on conveyor systems for streamlined material handling, the importance of well-designed and properly maintained pulleys becomes more evident. By understanding and harnessing the full potential of conveyor pulleys, you can maximize productivity, minimize downtime, and strengthen your competitive advantage in the dynamic world of material transportation. We can provide you with customized conveyor pulleys that fit your system perfectly. So, feel free to contact us for any inquiries or assistance.

Chapter Three: Materials of Conveyor Pulley

Conveyor pulleys are typically made from various materials, with each material chosen based on its specific properties and suitability for the intended application. The two main components of conveyor pulleys are the shell and the shaft. Both can be made from multiple materials. If you have any ideas, feel free to contact us at any time.

1. Shell Material:

The conveyor pulley's shell is a cylindrical covering that encloses the core components. The choice of shell material depends on factors such as the conveyor's environment, belt type, load capacity, and speed. Common materials for pulley shells include:

A. Steel: Steel is widely used due to its high strength and durability. It is suitable for heavy-duty applications and environments with wear or corrosion conditions. Steel pulley shells are typically made of carbon steel or stainless steel.

B. Aluminum: Aluminum is a lightweight option suitable for applications that require reducing pulley weight. It is commonly used in industries with lower load requirements or high corrosion resistance.

C. Rubber: Pulley shells with rubber coatings enhance the grip and friction between the conveyor belt and the pulley surface. They are used in applications where minimizing material slippage is crucial, such as inclined or downhill conveyors.

2. Shaft Material:

The shaft is the central component of the conveyor pulley on which the shell rotates. The shaft material needs to be sturdy enough to withstand bending and torsional forces during operation. Common shaft materials include:

A. Carbon Steel: Carbon steel shafts are widely used due to their high tensile strength and cost-effectiveness. They are suitable for standard load applications.

B. Stainless Steel: Stainless steel shafts offer better corrosion resistance, making them suitable for harsh or corrosive environments.

C. Alloy Steel: Alloy steel shafts are used in applications that require higher strength and impact resistance.

By carefully selecting appropriate materials, the design of conveyor pulleys can meet the demands of material handling applications and provide reliable performance across various industries. If you are interested in our conveyor pulleys, please contact us immediately, and we will respond within eight hours. Typically, our response time is much faster as well.

Chapter Four: Conveyor Pulley Manufacturing Process

The production process of conveyor pulleys involves several steps:

1. Material Selection: At Juming, we carefully choose suitable casing and shaft materials based on your specific conveyor system requirements.

2. Mechanical Processing: Raw materials are mechanically processed to the desired dimensions and specifications. This includes cutting, turning, drilling, and other machining techniques. Our skilled workers at Juming undergo rigorous training to ensure flawless products.

3. Welding: For pulleys with steel or aluminum casing, we typically weld the two ends together to form a cylindrical shape.

4. Surface Treatment: Depending on the material, pulleys can undergo surface treatments such as galvanization, coating, or rubber lining to enhance their performance and durability.

5. Balancing: Pulleys undergo dynamic balancing to ensure smooth operation and minimize vibrations by compensating for uneven mass distribution.

6. Final Assembly: Shafts are inserted into pulley casings, and pulleys are assembled with any additional components, such as bearings, locking elements, and sealing devices.

7. Quality Control: Our factory conducts strict quality control measures on the final products, ensuring compliance with specified specifications and standards.

With Juming's stringent manufacturing process, we guarantee the quality and performance of your required conveyor pulleys, enhancing their reliability and durability. Our products provide a solid assurance for the safe and efficient operation of your material handling system. If you have any requirements, please contact us promptly.

Chapter Five: the working principle of Conveyor pulley

Conveyor pulley is driven by an electric motor or other power device to rotate the pulley on the conveyor belt, thus driving the transportation of materials. It mainly includes the following steps:

1. Power transmission: Conveyor pulley is usually installed at both ends of the conveyor belt, with one end connected to an electric motor or other power source. The power source provides power, which is transmitted to the Conveyor pulley through a reducer or belt pulley.

2. Pulley rotation: After the power is transmitted, Conveyor pulley starts to rotate. Its rotation drives the conveyor belt to rotate together through the friction force of the conveyor belt.

3. Material transportation: Materials on the conveyor belt are driven for transportation as Conveyor pulley rotates. The materials can be various shapes and sizes, such as goods, ores, powders, and particles.

4. Direction control: By adjusting the direction of the power source, the rotation direction of Conveyor pulley can be controlled, achieving forward or reverse material transportation on the conveyor belt.

5. Speed control: By adjusting the speed of the power source, the rotation speed of Conveyor pulley can be controlled, regulating the transportation speed of materials on the conveyor belt.

In summary, the working principle of Conveyor pulley is to utilize the power source to drive the rotation of the pulley, thereby transporting materials on the conveyor belt. This transportation method is widely used in various material conveying systems. Finally, if you have any requirements or questions about Conveyor pulley, please contact us immediately. We are more than willing to communicate with you.

Chapter Six: the main uses of Conveyor pulley

Conveyor pulley serves as a power transmission and support device in conveyor belt systems, facilitating efficient material transportation. Specific uses include:

1. Power Transmission: Conveyor pulley connects to electric motors or other power sources to transfer power to the conveyor belt, driving the continuous material transportation.

2. Directional Control: The rotation direction of Conveyor pulley can be controlled by adjusting the power source. This enables forward or reverse material transport, facilitating material handling and transportation.

3. Speed Control: Adjusting the power source's speed controls the Conveyor pulley's rotation speed, allowing for adjustable material transport speeds to meet various material and process requirements.

4. Supporting the Conveyor Belt: Conveyor pulley is installed at both ends of the conveyor belt and connected to it through bearings and other devices. It bears the weight of the conveyor belt, providing support and guidance for stable operation.

5. Steering and Guiding: Conveyor pulley's shape and design facilitate steering and guiding in the conveyor belt system, ensuring materials are transported in the specified direction, avoiding deviation from the track.

From this, it can be seen that Conveyor pulley plays a vital role in the conveyor belt system, facilitating efficient material transfer and transportation control. If you have any needs, please feel free to contact us. We warmly welcome your inquiries.

Chapter Seven: Relevant Regulations on Conveyor Pulley

The regulations and guidelines regarding Conveyor pulleys vary from country to country and region to region. If you have specific requirements, please feel free to contact us. We will be pleased to receive your message.