Juming Industrial Conveyor Belt

Conveyor belt is a device made of a continuous belt-like material used to transport materials, goods, or other objects between different locations. it consists of a set of pulleys and the belt material, allowing movement in horizontal, inclined, or vertical directions. conveyor belts are typically made of flexible and wear-resistant materials such as rubber, polymers, or metals. powered by a drive unit, usually an electric motor, conveyor belts serve as efficient and automated tools for material transportation. they find wide applications in industrial production, logistics, mining, construction, agriculture, and other fields.

The main function of conveyor belts is to transport materials from one location to another, replacing manual handling or other forms of material transportation. They can convey materials between different processes on factory production lines, such as loading, sorting, packaging, and assembly. Additionally, conveyor belts are also used in loading and unloading goods, warehousing, sorting, and distribution centers, enhancing the efficiency and accuracy of logistics operations.

The conveyor belts you need can be designed and customized to specific requirements. For example, we can provide conveyor belts with special surface textures or grooves to offer additional friction, preventing material slippage or misalignment. Additionally, some conveyor belts can be equipped with auxiliary devices such as sensors, weighing systems, and sorters to achieve more precise control and automation.

The conveyor belts exported by Juming are widely used in various industrial sectors and applications worldwide, covering a diverse range of scopes and purposes. The efficiency of conveyor belt systems contributes to increased productivity, cost savings in labor, and reduced delivery time. They can swiftly and reliably move large quantities of goods for transportation, further assembly, or storage.

The main reasons for using such a wide range of conveyor systems are to save labor costs, efficiently handle goods, and protect products and materials from damage. They provide the highest quality service at the lowest cost. Just as we provide our services for your project at the lowest cost while ensuring the highest quality.

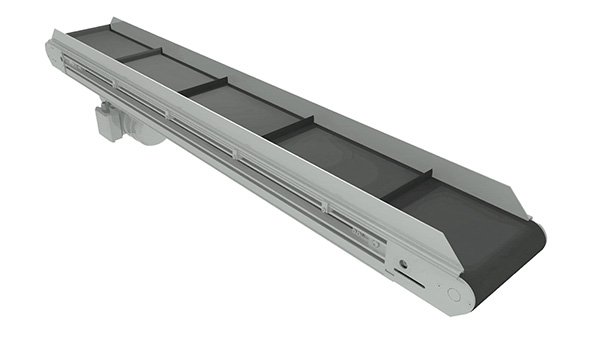

1. Flat Belt Conveyor: Used for horizontal or slightly inclined material transportation, commonly found in industrial production lines and logistics fields. It is the most common type of conveyor belt.

2. V-Belt Conveyor: V-shaped conveyor belt is made by V-shaped molding and directly integrated into the cover layer of the conveyor belt to increase the friction between the conveyor belt and the conveyed material.

3. Spiral Conveyor: It utilizes a spiral structure to push or elevate materials, suitable for conveying and discharging powdered or granular materials.

4. Gravity Roller Conveyor: It utilizes the weight of the materials to slide and transport them on a horizontal or inclined surface. It is commonly used for the conveyance and loading/unloading of lightweight materials.

5. Corrugated Sidewall Conveyor Belt: Corrugated Sidewall Conveyor Belt are designed with wave-shaped cleats on both sides of the belt to prevent material spillage due to site limitations or the need for high-angle material conveying. Corrugated Sidewall Conveyor Belt must be able to withstand high stress and repeated flexing that occur during high-capacity and high-angle conveying.

Click to view Corrugated Sidewall Conveyor Belt

Chapter Third:The raw material of the conveyor belt

Regardless of the materials used, our company Hebei Juming Import And Export Trade Co., Ltd. manufactures various types of conveyor belts that are designed to efficiently and smoothly move products, materials, supplies, and components from one place to another. The selection of the appropriate conveyor belt type is determined based on the characteristics of your products. Although there are many different materials used in the production of our conveyor belts, they can be categorized into five major categories: metal, plastic, rubber, textile, and leather. Each category has its own subgroups and variations.

1. Metal Conveyor Belt: Metal conveyor belts are typically made from metal materials such as steel and stainless steel, offering high strength and durability. They are suitable for heavy-duty and high-temperature environments, capable of handling heavy loads and resisting corrosion. Metal conveyor belts are commonly used in industries such as mining, metallurgy, and automotive.

2. Plastic Conveyor Belt: Plastic conveyor belts are usually made from polymer materials such as polyurethane, polyethylene, and PVC, known for their lightweight, corrosion resistance, and wear resistance. They are suitable for applications in industries with high cleanliness and hygiene requirements, such as food processing and packaging.

3. Rubber Conveyor Belt: Rubber conveyor belts are made from rubber materials such as natural rubber and synthetic rubber, exhibiting good elasticity, wear resistance, and corrosion resistance. They are suitable for various industries including mining, metallurgy, construction, and agriculture.

4. Fabric Conveyor Belt: Fabric conveyor belts are made from textile materials such as cotton, nylon, and polyester, offering good flexibility and tensile strength. They are suitable for conveying lightweight and medium-weight materials, commonly used in industries such as packaging, logistics, and warehousing.

5. Steel Cord Conveyor Belt: This is a special structure conveyor belt with a core composed of multiple steel cords. It possesses high strength, wear resistance, tensile strength, and high-temperature resistance, making it suitable for long-distance, high-load, and high-speed transportation applications. Steel cord conveyor belts can withstand high tension, high speed, and heavy loads, while maintaining wear resistance, tensile strength, and high-temperature resistance. The advantages of steel cord conveyor belts include excellent strength and durability, low energy consumption, as well as long service life and reliable operation.

Click to view Steel Cord Converor Belt

These conveyor belts made from different materials have differences in terms of wear resistance, corrosion resistance, temperature range, weight, applicable environments, and costs. Therefore, selecting the appropriate conveyor belt material requires considering the specific requirements and conditions of the application to ensure optimal performance and durability. If you have any requirements, please click here to contact us, and we will respond within 8 hours, usually even faster than eight hours.

Chapter Four: Working Principle of Conveyor

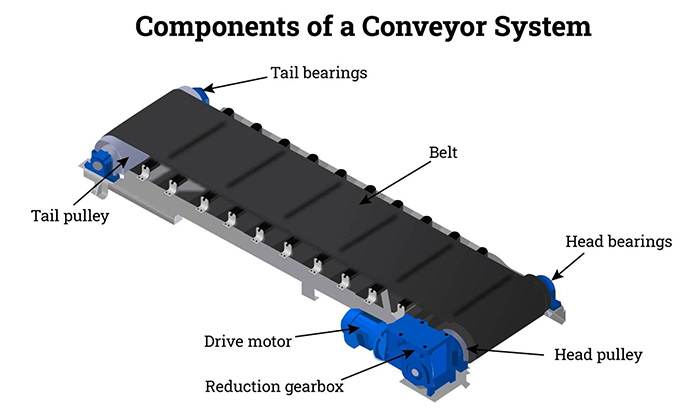

The working principle of a conveyor is based on the continuous cyclic operation of the conveyor belt. It mainly consists of the following components:

1. Drive System: Usually consists of motors, gears, or hydraulic systems, providing power to drive the conveyor belt.

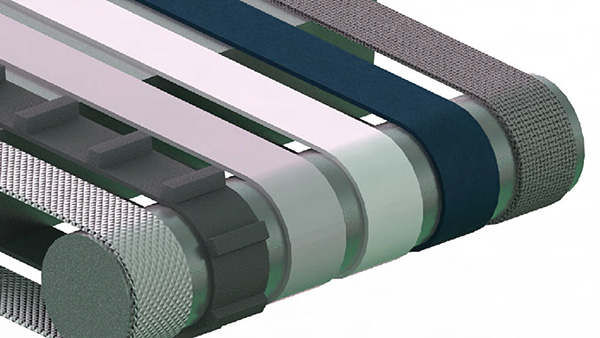

2. Conveyor Belt: Composed of a flexible belt material such as rubber, plastic, or fabric. The conveyor belt is connected to the drive system and support devices, forming a closed loop.

3. Support Devices: Used to support and maintain the stable operation of the conveyor belt. It can be rollers, slides, chutes, or brackets, among others.

The working principle of the conveyor belt is as follows:

1. Power Transmission: The drive system provides power and transfers rotational force to the conveyor belt, initiating its movement.

2. Material Loading: Place the material to be conveyed at the feeding end or loading area of the conveyor belt.

3. Operational Cycle: The conveyor belt starts running according to the set speed and direction, moving the material along its length from the feeding end to the unloading end.

4. Material Unloading: At the unloading end or target location, the material is removed from the conveyor belt, which can be done through gravity, mechanical devices, or operator intervention.

5. Cycle Repeats: The conveyor belt continues running, moving the next batch of material from the feeding end to the unloading end, repeating the cycle.

The speed and direction of the belt can be adjusted as needed to accommodate specific material conveying requirements. Auxiliary devices such as guiding systems, rollers, side guards, and sensors can be used to ensure stability, positioning, and safety of the material during the conveying process. If you need a complete system, feel free to contact us, and our engineers will create custom drawings tailored to your requirements.

Chapter Five: Uses of Conveyor Belts

Conveyor belts have a wide range of applications and play a crucial role in various industries and sectors.

1. Material Conveyance: Conveyor belts are used to transport materials from one location to another. For example, they can move raw materials to workstations on a production line or transfer finished products to packaging areas.

2. Packaging and Sorting: Conveyor belts are essential in packaging and sorting processes. They facilitate the movement of packaging materials and products between different workstations, enabling efficient packaging and sorting operations.

3. Transportation and Logistics: Conveyor belts are employed in the transportation and logistics industry to move goods from warehouses or loading areas to transportation vehicles (such as trucks, ships, or airplanes) or storage facilities.

4. Mining and Quarrying: In mining and quarrying operations, conveyor belts are used to transport minerals, stones, and coal from mining sites to processing equipment or transport vehicles.

5. Agriculture and Agricultural Product Processing: Conveyor belts find widespread use in the agriculture sector for conveying crops, feed, fertilizers, and other agricultural products. They can, for instance, transfer harvested crops from fields to storage equipment or processing plants.

6. Food Processing and Packaging: Conveyor belts play a vital role in the food processing and packaging industry. They transport food raw materials, finished products, and packaging materials, facilitating automated production and packaging processes.

7. Warehousing and Distribution Centers: Conveyor belts are utilized in storage and distribution centers for storing, organizing, picking, and distributing goods, enhancing warehouse management efficiency.

8. Sewage Treatment: Conveyor belts are employed in sewage treatment facilities to transport sludge, solid waste, and processed materials, contributing to the automation and efficiency of sewage treatment plants.

At our factory, we have experience in manufacturing various types of conveyor belts and belt conveyors. Our clientele spans across the globe, including North America, South America, Australia, Asia, and Europe. Whether you need belt conveyors, conveyor belts, or other components such as rollers, you can reach out to us. We are committed to providing top-notch service and exceeding your expectations.

Chapter Six: Relevant Regulations on Belt Conveyors

The standards and regulations for belt conveyors may vary depending on the country and region. Here are some common standard and regulatory organizations that have established specifications and guidelines related to belt conveyors:

1. United States Standards and Regulations:

- ANSI/CEMA 402-2003: "Safety Standard for Belt Conveyors" developed by the Conveyor Equipment Manufacturers Association (CEMA), provides specifications and guidance on the safety aspects of belt conveyors.

- OSHA Standards: The Occupational Safety and Health Administration (OSHA) has developed a series of standards related to workplace safety, including provisions applicable to belt conveyors.

2. European Standards and Regulations:

- EN 12882:2008: "Safety Requirements for Conveyor Belts for General-Purpose Use" published by the European Committee for Standardization (CEN), includes safety requirements and test methods related to belt conveyors.

- DIN 22101: The German Institute for Standardization (DIN) has published standards related to the design and calculation of belt conveyors.

3. International Standards:

- ISO 5049-1:2012: "Safety of Machinery - Principles for Risk Assessment and Risk Reduction" published by the International Organization for Standardization (ISO), includes safety requirements and test methods related to continuous handling equipment, including belt conveyors.

Additionally, specific industries and applications may have their own standards and regulations applicable to the use of belt conveyors, such as in food processing, mining, and construction industries. It is important to adhere to the relevant safety requirements and regulations based on local laws, standards, and manufacturer guidelines in specific operating environments.

Whatever your requirements may be, our engineers can customize solutions tailored to your needs. So, feel free to contact us as soon as possible if you have any requirements or inquiries related to conveyor systems.